Events

27.-29. February 2024

Workshop on Core and Plant Simulation with Emphasis on Fuel Behaviour in Light Water Reactor Based Small Modular Reactors

(Vienna & online)

The IAEA organises an international workshop in cooperation with McSAFER and the support of the US Oak-Ridge National Laboratory (ORNL), to foster the exchange of information on approaches, challenges and specific experiences related to multi-physics and multi-scale simulations of SMR-cores.

The purpose of the event is to bring together experts in the field of fuel behaviour simulation, to foster the exchange of information on multi-physics and multi-scale simulations of SMR-cores (loaded with ATF fuels or without) and integral plant behaviour, using different computation approaches, to compare results of SMR fuel behaviour simulation and to perform common analyses.

Registration deadline: 19.01.2024

19. May 2022

22.-24. March 2022

Second McSAFER Training Course

Lappeenranta-Lahti University of Technology LUT (Finland)

The McSAFER project is organizing a training course on „SMR neutronics and thermal hydraulics“. The training course focuses on core neutronics and thermal hydraulics of light water SMRs. It will consist of lectures by experts from the McSAFER project, a tutorial to the new Finnish computational reactor analysis framework Kraken developed at VTT and an experimental thermal hydraulics session at the LUT research laboratories.

The course will be organized as contact teaching at LUT but is subject to the current corona virus regulations. For more information about the trainings course and the registration process, check our flyer:

Registration deadline: 28.02.2022

25.-27. January 2021

First McSAFER Training Course (online)

Universidad Politécnica de Madrid (UPM)

On January 25th-27th, the McSAFER project held its first trainig course on „SMR LWR Technologies“. The event was organized by professor C. Queral (UPM) with support of the McSAFER consortium members. Amost 200 participants worldwide took part in the online event.

News

McSAFER MOOC on "Multi-physics analysis of water-cooled SMR-transients

12. February 2024

A central objective of McSAFER is to further education on SMRs. Therefore, we are happy to announce that we are offering a massive open online course (MOOC) with the title „Multi-physics analysis of water cooled SMR-transients“. The course consists of 14 parts that cover various aspects of our reasearch. You can check out of MOOC here.

PROGRESS UPDATE

30 AUGUST 2023

WP2 – Experimental investigations of SMR key phenomena and code validation

WP2 has been devoted to thermal hydraulic experiments and code validation for SMRs. Experiments are conducted by KIT with the COSMOS-H facility in Karlsruhe, Germany, by LUT with the MOTEL facility in Lappeenranta, Finland and by KTH with the HWAT facility in Stockholm, Sweden. The experiments at the three test facilities provide measurement data for the validation of thermal hydraulic analysis codes from computational fluid dynamics (CFD) to subchannel and system thermal hydraulics. Six project partners (KIT, LUT, UJV, UPM, TBL, KTH) participate in the effort validating a total of ten different thermal hydraulic tools, such as, OpenFOAM, VIPRE and TRACE, to name a few.

COSMOS-H is a water loop with the maximum pressure and temperature of 170 bar and 360 °C, respectively. In McSAFER, the loop is used for boiling experiments in prototypic SMR fuel geometries and conditions up to the boiling crisis. The facility features a test section of modular design with two high pressure sight glass modules that are utilized to obtain high quality data with optical measurement techniques. Inside the test section, first a single heated rod is placed, followed by a rod bundle in later experiments. The COSMOS-H facility was completed at the end of 2022 and obtained operating license in June 2023 after successful pressure and safety tests. The first COSMOS-H experiments are being carried out at the time of release of this newsletter.

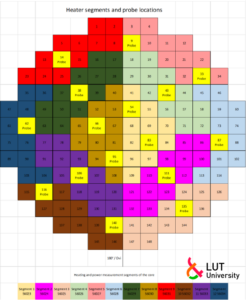

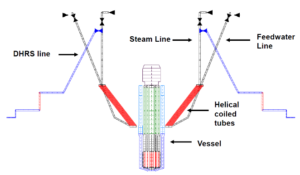

MOTEL is an integral test facility of modular design which for the McSAFER experiments represents a model of an integral PWR type SMR operating at natural circulation with the core, the helical steam generator, and the pressurizer all inside a single pressure vessel. The facility is used to investigate the behaviour of the steam generator and core cross flows. The steam generator tests investigate the stability and superheating performance at different steady heating powers up to the facility maximum of 1 MW. The core cross flow tests consider different radial power distributions as the core has a relatively large diameter with a total of 132 heater rods distributed into 12 individually controlled heating segments. The MOTEL facility became operational already in the beginning of McSAFER and all the planned experiments have been successfully completed.

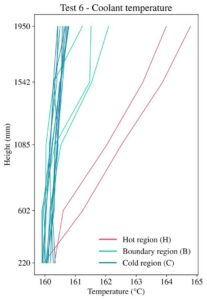

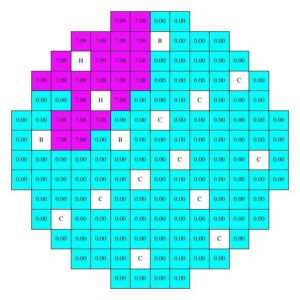

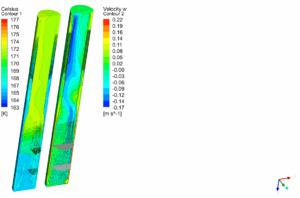

MOTEL core crossflow experiment results (core axial temperature profile and the related radial locations of the hot, boundary and cold region temperature measurements). The core diagram shows the heater powers in kW.

MOTEL core crossflow experiment results (core axial temperature profile and the related radial locations of the hot, boundary and cold region temperature measurements). The core diagram shows the heater powers in kW.

HWAT is a water loop for two phase flow investigations capable of 2 kg/s flow rate, 250 bar pressure and 450 °C temperature with a maximum heating power of 1 MW. HWAT is used to investigate heat transfer up to critical heat flux, flow stability in natural circulation, power void reactivity feedback and non-linear power profile in typical SMR conditions, considering also transition from forced to natural circulation. First tests include forced circulation steady states with an electrically heated riser as the test section, while for the further experiments the facility will be modified with the inclusion of another loop via a steam generator. The primary loop then models the in-vessel circulation of an SMR. These tests focus on forced to natural circulation transients. Information about the local flow characteristics inside the test section is obtained with a specific multi-sensor probe unit. At the time of release of this newsletter, the first HWAT test series has just been completed and the facility is being modified for the remaining experiments.

The code validation progress follows the progress of the experiments with most of MOTEL related simulations either already finished or well underway while for the COSMOS-H and HWAT experiments simulation models have been prepared with testing and blind calculations. Highlights of the CFD code validation so far include the detailed CFD modelling of the entire MOTEL primary circuit with CFX by KIT and the porous media based CFD modelling of MOTEL with Fluent by UJV, both with good agreement with the experimental measurements. Similarly, good results have been obtained in the subchannel code simulations of the MOTEL cross flow experiments with CTF by TBL. For thermal hydraulic system codes, detailed models have been built of all the facilities and the first test simulations, e.g., by LUT with APROS and UPM with TRACE look promising.

WP3 – Multiphysics Core Analysis Methodologies for SMR Applied for Safety Case Rea

Core level transient analyses have been conducted at three levels of fidelity:

- Industry standard methods represented by nodal diffusion neutronics coupled to assembly or quarter assembly level thermal hydraulics and representative rod fuel feedback.

- Advanced low-order methods represented by pin resolved neutronics coupled to subchannel level thermal hydraulics and rod level fuel feedback.

- High fidelity methods utilizing Monte Carlo neutronics with detailed geometry coupled to subchannel level thermal hydraulics and rod level fuel feedback.

Modelling the same transient scenario with different levels of fidelity provides information on which safety parameters are well predicted by the industry standard methods and which safety parameters require high fidelity methods in order to be properly resolved.

It is obvious that local rod and subchannel level data such as maximum fuel temperature and minimum critical heat flux ratio can be directly predicted only by the tools with pin resolved solutions. Industry standard tools would need to apply additional approximative hot channel and hot rod analyses in order to obtain the local limiting values.

The overcooling transient for the Nuward-like F-SMR reactor was analysed with nodal diffusion (fidelity level 1) and pin level neutron transport (fidelity level 2). The maximum power reached during the transient was similar using both toolchains, but the local power peaking was clearly higher in the higher fidelity model as it could resolve the variation in power between different fuel rods in the same assembly.

The rod ejection accident modelled for the SMART-like KSMR reactor has been modelled with nodal diffusion (fidelity level 1), pin level neutron transport (fidelity level 2) and Monte Carlo neutronics coupled to subchannel level thermal hydraulics (fidelity level 3). In the analyses, the lower the fidelity of the modelling, the higher the maximum reactor power reached in the simulation with the largest difference observed between the nodal (level 1) and pin level (level 2) solutions. On the other hand, the highest fidelity solution produced smallest margins for the local heat transfer crisis (mDNBR).

Finally, the rod ejection accident modelled for the NuScale-like reactor has been modelled with nodal diffusion (fidelity level 1) and pin level neutron transport (fidelity level 2) with the Monte Carlo (fidelity level 3) analysis still ongoing. In contrast to the KSMR transient this scenario is not prompt super critical. The reactivity insertion from the rod ejection is slightly higher with the higher fidelity model leading to the maximum power during the transient being higher with the higher fidelity model as well. The effect of the level of discretization is best seen in local data, such as maximum fuel temperatures.

The remaining work will re-analyse the transient in the NuScale-like core using an accident tolerant fuel loading and draw conclusions on which data can be well predicted using industrial tools and which data requires pin level resolution during the transient calculation.

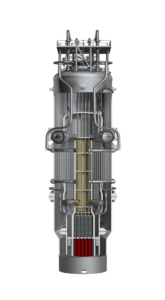

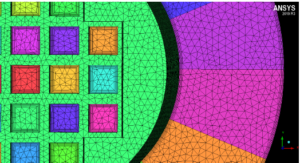

WP4 – Multiscale RPV Analysis Methodologies for SMR

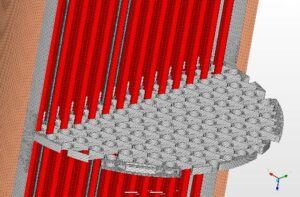

WP4 has been devoted to RPV thermal hydraulic analysis of two SMR design NuScale (USA) and SMART (Korea). Integral concept of new SMR consider new features such as helical heat exchangers or devices added to homogenize the flow and reinforce the mixing of the coolant before entering to the core. The traditional 1D or 3D system thermal hydraulic codes often cannot catch the physics going on under nominal or accidental conditions, therefore the use of novel methods such as multiscale coupling of system-TH codes with subchannel codes and system-TH codes with CFD codes is applied to investigate the multi-dimensional and mixed convection flow inside the RPV. These multiscale methods allow better understanding and description of the thermal hydraulic phenomena inside the RPV by increasing the spatial resolution of the computational domains.

The selected scenarios are:

- Boron dilution for NuScale reactor

- ATWS event decrease in the heat removal by the secondary system for SMART reactor

Each of the participants independently developed their own model. To provide fair comparisons between different reactor analysis toolchains and different partners of the project, a sufficiently detailed database has been prepared. As selected reactors are developed as commercial enterprises, not all required information is publicly available. From the point of view of the goals of the McSAFER project, especially regarding the comparability of results, the existence of fixed specifications is more important than the exact details of the specifications, meaning that expert judgement can well be applied in determining suitable values for missing data.

In WP4, the scope of the analyses is limited to RPV only, the calculation models include all essential components. Ex-vessel systems and components are simulated as boundary conditions BCs.

The work in WP4 is divided as follows:

- Task 4.1 – the Reactor pressure vessel (RPV) is modelled using a traditional 1D approach where each region of RPV (core, riser, downcomer, lower plenum, pressurizer) is modelled by a 1D component.

- Task 4.2 – the RPV is modelled through coarse 3D meshes, which will also allow representation of azimuthal flows.

- Task 4.3 – coupled 3D system thermal hydraulic and subchannel codes are used for detailed simulation of core behaviour.

- Task 4.4 – coupled 3D system thermal hydraulic and CFD codes are used for detailed simulation of flow mixing in the lower plenum

Task 4.1 to Task 4.3 have been successfully completed, work on Task 4.4 is currently underway. The overall evaluation and comparison of calculations will be carried out after the completion of task 4.1.

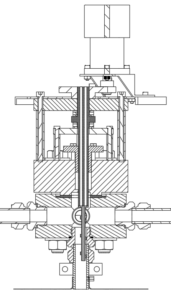

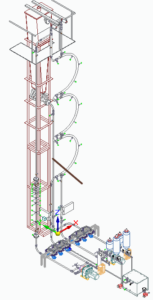

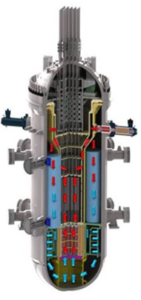

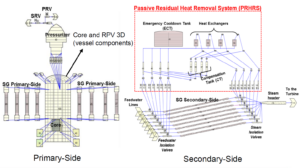

WP5 – Multi-Scale Plant Analysis Methodologies for SMR Applied to Postulated Accident Scenarios

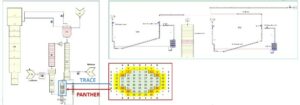

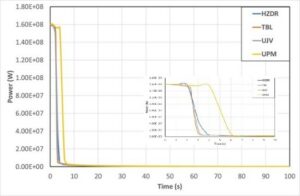

In continuation of the WP4 work, the vessel models of the NuScale and the SMART SMR designs are extended to the whole plant. Steam line break analyses have been conducted for both SMR designs by means of thermal hydraulic system codes coupled with 3D neutron kinetic nodal diffusion codes. For the NuScale reactor, four different models have been developed by four different organizations. The figure below (top) shows the TRACE/PANTHER model of Tractebel. The bottom figure shows the power evolution obtained in the four coupled calculations. The main events are in good agreement between the code systems. On the primary side, differences are observed in the time behaviour of the core temperatures, which are triggered by the differences in the heat transfer within the steam generators.

Similar models have been developed and applied to a steamline break analysis of the SMART reactor.

In the final project phase, 3D CFD models are integrated into the downcomer models for both designs in order to adequately describe the asymmetries in coolant flow behaviour induced by the transients.

3rd PROJECT PROGRESS MEETING

19.-21. June 2023

On June 19th to 21st, the McSAFER consortium held its 3rd project progress meeting. The meeting was organised online via ZOOM. We were joint by our Project Officer Panagiotis Manolatos as well as his successor Angelgiorgio Iorizzo.

We would like to express special thanks to the members of out Technical Advisory Board and our Users Group for their feedback and contributions at the meeting and beyond.

COSMOS-H EXPERIMENTS AT KIT

12 October 2022

Preparations for the flow boiling and critical heat flux experiments at KIT are now progressing well. After several delays in delivery due to market conditions, many systems have been completed now. After the completion of the high-pressure loop of COSMOS-H and the first set-up of the test section, the strength tests for approval according to the Pressure Equipment Directive were carried out at the end of May.

The pressure test was carried out at 328 bar and 20°C. The test section and test loop were completely filled with demineralised water using the plant’s water management system. Then the circuit was filled with two external pumps to a pressure of 329 bar at the lowest point. The test section and the system withstood this pressure under the supervision of the expert inspector. This means that the system can be stressed to conditions of up to 370°C and 170 bar in the subsequent test operation.

In the meantime, the inspection of the inside of the test section and the vessels has also been successfully completed. Systems such as the trace heating and thermal insulation were applied to the test loop and all sensors were applied. A small leakage that the electric steam generator showed during the pressure test at the heater entries from 260 bar is currently being sealed and the test section with the first test arrangement is being set up. The „hot“ commissioning of the facility and the test section will begin shortly.

MOTEL EXPERIMENTS AT LUT

08 October 2022

Two series of experiments were conducted with the MOTEL test facility in the LUT University nuclear safety research laboratory in Lappeenranta, Finland, in 2021-2022. The first series studied the behaviour of the helical coil type steam generator of MOTEL, and the second series focused on studying core crossflows applying asymmetrical radial core power distributions.

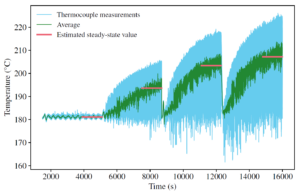

Steam generator experiments

The first test series consisted of two steam generator experiments, which were performed in the autumn 2021. Steady states with different uniform core heating power levels were run. In the first experiment, the used power levels were 250 kW, 500 kW, 750 kW and 1 MW, which is the maximum heating power of MOTEL. In the second experiment, lower power levels were used; 75 kW, 100 kW, 125 kW and 150 kW. Particularly, the temperature behaviour of the steam generator, both on the shell and tube sides, was studied. Temperature distributions along the steam generator tubes were measured. In the first experiment with higher core powers, there was a clear increasing trend of the temperatures apart from the lowest 250-kW power level, as can be seen in the example Figure 1. The figure shows the averaged secondary side steam generator temperatures on the middlemost level of the SG. Same kind of increasing temperatures on were detected on the shell side of the SG. Hence, not all the power steps can be considered as real steady states but more as quasi-steady states. Also, a clear fluctuating behaviour of the temperatures was observed, especially on the higher core power levels.

In the first series’ second experiment with the lower power levels, the temperature behaviour was more stable in the sense that there was no such increasing temperature trend as in the first experiment. The secondary side feedwater reached the saturation temperature in the bottom region of the steam generator, and the temperatures stayed on the same level along the whole length of the SG. A slight fluctuating behaviour of temperatures was observed during the second experiment, albeit not nearly as strong as in the first experiment.

Core crossflow experiments

In the second MOTEL test series within McSAFER, MOTEL core crossflows were studied, using both symmetrical and different asymmetrical radial core power distributions. The MOTEL core is divided into twelve separately adjustable radial power regions as illustrated with different colours in Figure 2. This structure enables application of various radial core power distributions in the experiments.

In the two experiments of the second series, the aim was to achieve as large temperature differences in the radial directions of the core as possible by means of applying asymmetrical power distributions. Uniform power distributions were run for reference in the beginning of the experiments. In the first experiment, asymmetrical distributions with the core divided into two halves (left- and right-hand sides in Figure 2) were tested. The following configurations were tested: one half 31 %, the other half 16 % of the maximum power; 37 % and 10 %; 48 % and 0 %. The total core power on these runs was approximately 230 kW, and the duration of each step was one hour. In addition, a power distribution with 92 % power in two segments and 0 % in all the other segments was run, the total power being approximately 170 kW.

In the second experiment, ring-shaped radial power distributions were tested. First, a power distribution with 100 % power in the middle and 0 % power in the inner and outer rings (see Figure 2) was run, the total power being approximately 150 kW. Then, the power was increased to approximately 235 kW and a reference run was conducted with a uniform power distribution. After that, a ring-shaped power distribution with 100 % power in the middle and 10 % power in the other regions was run. Finally, a power distribution with 52 % power in the middle, 31 % in the inner ring and 10 % in the outer ring was run, the total power being 235 kW. The duration of the reference runs was half hour, and the duration of the actual runs was one hour.

The maximum used power in the crossflow experiments was approximately 235 kW. This was because the experiments were desired to be run as steady state as possible. With higher powers, the temperatures in the facility would have an increasing trend, as can be seen above in Figure 1. Increasing temperatures would make the interpretation of the core region radial temperature differences difficult.

The analysis of the data from the core crossflow experiments is not ready yet. Nevertheless, it can be concluded that the temperature differences in the core in the radial direction were fairly low. This is most probably due to the structure of the MOTEL facility and the consequent relatively high mass flow compared with the height of the core. It seems that with these experiments, not as large temperature differences were achieved as desired.

2nd PROJECT PROGRESS MEETING

07.-09. SEPTEMBER 2022

The McSAFER consortium convened on September 7th-9th for its 2nd project progress meeting. The metting was held at the Karlsruhe Institute for Technology with some members joining online.

We are very grateful that our Project Officer – Panagiotis Manolatos – and several members of McSAFERs Technical Advisory Board as well as members of the User Group were able to join the meeting.

We thank all participants for their contributions and the fruitful discussion.

2nd McSAFER Trainings Course

11. May 2022

As part of the educational activities developed within the McSAFER project framework, a McSAFER training course on „SMR neutronics and thermal hydraulics“ was organized by the Lappeenranta-Lahti University of Technology (LUT, Finland) March 22nd to 24th, 2022. The course was offered free of charge, but it was limited to max. 20 participants due to the limited laboratory capacities. In total, 18 students participated in the course.

The first day of the course consisted of six lectures on various analysis methods and tools applied for SMRs within the context of the McSAFER project:

- „CAREM-like model with PARCS-SCF“, Juan Blanco (KIT)

- „F-SMR core analysis“, Anthime Farda (CEA)

- „NuScale analysis with TRACE“, Jorge Sanchez (UPM)

- „CFD analysis of NuScale“, Ladislav Vyskocil (UJV)

- „Multiscale analysis of SMART“, Manuel Garcia (KIT)

- „Fuel cycle optimization“, Hector Lestani (CNEA)

The second day of the training course was devoted to a workshop on the Kraken multi-physics framework and its application for SMR analyses. The focus of the third day was in thermal hydraulics experiments.

Call for Papers: "Advanced Numerical Modelling Techniques for Nuclear Reactors"

The Guest Editors of the Journal „Energies“ have announced a Special Issue under the section „Nuclear Energy“ with the title „Advanced Numerical Modelling Techniques for Nuclear Reactors“. The nuclear community is invited to submit manusripts to this Special Issue until 25.01.2022. More information can be found in the flyer and this link.

PROJECT PROGRESS

22. November 2021

Work Package 3 – Multiphysics core analysis methodologies for SMR applied for safety case REA

The Work Package 3 of McSAFER focuses on evaluating the differences in the predictive capabilities of different fidelity reactor core solvers in core level transient scenarios. Transients are modelled at the core level of four different SMR concepts using solvers at three levels of fidelity:

- Traditional low-order methods based on nodal diffusion neutronics and one dimensional thermal hydraulics.

- Advanced low-order methods with direct pin-level resolution of the neutronics coupled with subchannel level thermal hydraulics.

- High fidelity methods using Monte Carlo neutronics solution coupled with advanced thermal hydraulic solvers.

During the first year of the project, the openly available specifications for the four SMR concepts were supplemented using expert judgment in order to produce comprehensive and consistent specifications at the reactor core level that can be utilized in constructing the calculation models for the wide range of reactor core analysis codes applied in the project.

The construction of the calculation models for traditional and advanced low-order methods has been proceeding well with the largest effort going into establishing a proper group constant generation methodology for both the nodal neutronics and pin-level neutronics solvers for each of the different SMR concepts.

Furthermore, an investigation has been made into advanced transient heat deposition models that could account for both the prompt part of transient heating and also accurately model the development of the decay heat distribution in the reactor core during and after transient scenarios.

Work Package 4 – Multiscale RPV analysis methodologies for SMR

Within WP4 we will perform thermal hydraulic analyses of reactor pressure vessel behaviour for two SMR designs, NuScale and SMART. This WP is divided into four Task, in which the same problems are analysed both by the traditional 1D or 3D (coarse mesh) approach and by using multiscale coupling of system-TH codes with subchannel codes and system-TH codes with CFD codes. The work in WP4 is closely coordinated with WP5, as the models developed in WP4 serve as input for WP5.

At the beginning of the project, NuScale and SMART databases were created from open literature, on the basis of which input models for computer codes are prepared. This approach will ensure comparability of the results of individual participants.

In the current phase of the project, efforts are mainly focused on the development of 1D and 3D models for system programs (eg. TRACE).

Work Package 5 – Multi-scale plant analysis methodologies for SMR applied postulated accident scenarios

WP5 deals with the modelling of the whole plant of two SMR designs, NuScale and SMART. It continues the work of WP4, where the reactor pressure vessel of the same two designs is modelled and different accident scenarios are analysed. In the first phase of the project, efforts are naturally concentrated on vessel modelling.

Beside this, the system code models for the NuScale and SMART reactor designs are prepared to be equipped with components outside the reactor pressure vessel. This concerns the decay heat removal system (DHRS), the feedwater system and the main steam lines.

In addition, the modelling efforts are directed towards the coupling of the system code model with those from the CFD code. For the NuScale model a 1:1 coupling of each fuel assembly is being implemented.

1st McSAFER PROGRESS MEETING

20.-22. September 2021

On September 20th-22nd, the McSAFER consortium held its 1st project progress meeting. Due to the continuing COVID pandemic it was unfortunately not possible to meet in person and the meeting was held via ZOOM. At the meeting the workpackage and task leaders reported on the project’s progress.

We were very pleased that McSAFERs Project Officer – Panagiotis Manolatos – was able to join us.

THE THERMAL HYDRAULIC TEST FACILITIES IN McSAFER

15. September 2021

COSMOS-H (Karlsruhe Institute of Technology, Germany)

The experimental test facility COSMOS-H (“Critical Heat Flux on Smooth and Modified Surfaces – High Pressure Loop”) is developed and set up for the detailed investigation of thermohydraulic phenomena like boiling and complex flow phenomena that can occur in (nuclear) power plants.

The facility consists of a high-pressure loop in which experiments can be carried out with demineralized water at pressures up to 17 MPa and temperatures up to 360°C. In addition, there are two cooling loops connected in series working with thermal oil and cooling brine. The entire system has a heating capacity of almost 2 MW for heating and evaporating the working medium. The test section accounts for 600 kW of this.

The experiments conducted within McSAFER focus on heat transfer in different SMR concepts. In particular, boiling flows under forced convection up to the critical heat flux will be investigated.

For this purpose, two different experimental setups will be fabricated. Detailed investigations will be carried out on a single heated tube made of Zircaloy-4 surrounded by an annular gap through which the flow passes, also using optical measurement methods. These will be supplemented with investigations on a rod bundle consisting of 5 heated tubes. Similar to a small section of a fuel element, one tube is surrounded by four other tubes in the periphery.

HWAT (Kungliga Tekniska högskolan, Sweden)

HWAT (“High-Pressure Water Test Loop”) is a high-pressure, high-temperature water loop for investigation of two-phase flows and heat transfer relevant to nuclear applications. In particular, the loop has been used for intensive studies of Critical Heat Flux (CHF), bringing about one of the largest experimental databases in this area in the world. The loop is constructed to withstand high pressures, up to 25 MPa, and high temperatures (up to 375°C) to enable experiments involving supercritical water.

In McSAFER, the HWAT experimental programme aims to develop experimental data for the calibration and validation of thermal-hydraulic codes with the focus on natural circulation transients, specifically transition from forced-to-natural circulation and transition from natural-to-natural circulation in conditions relevant for novel SMRs.

MOTEL (Lappeenrannan-Lahden teknillinen yliopisto LUT, Finland)

The next-generation multifunctional large-scale test facility MOTEL (“Modular Test Loop”) has been constructed at LUT University nuclear safety research laboratory in Lappeenranta in 2019-2020 for studies on nuclear reactor safety related thermal hydraulic phenomena. The principal idea of the MOTEL facility is modularity: the facility comprises interchangeable components, modules, and the facility design enables adding new components when needed. By replacing individual modules, MOTEL is thus able to represent several different types of nuclear power plants as needed.

In McSAFER, the MOTEL experiments will produce SMR-specific data for the validation of system, CFD and subchannel codes. The experiments are divided into two test series. The first series will focus on the behaviour of the helical coil steam generator. The aim is to study heat transfer from the primary side to the secondary side by performing several steady state periods with different core power levels. The second test series will comprise core crossflow experiments especially for the studies on mixing between core subchannels. This test series will be divided into two parts: experiments with an even radial core power distribution and experiments with a skewed radial core power distribution.

McSAFER Mobility Programme

OPEN FOR APPLICATIONS

The McSAFER project has launched a mobility programme for PhD students, postdoc researchers and staff members of its partner organizations. The mobility programme funds temporary stays in McSAFER partners‘ labs and research facilities, applications can be submitted at anytime. For more information, check our Mobility Manual.

First Project Newsletter released

31. August 2021

The McSAFER project has released its first project newsletter. Do you want to keep up to date with the latest news and updates? Subscribe to the annual newsletter!

McSAFER at a GLANCE

01. August 2020

The aim of the McSAFER project is to advance the safety research for Small Modular Reactors (SMRs) by combining safety-relevant thermal hydraulic experiments and numerical simulations of different approaches for safety evaluations.

Start date: 01/09/2020

Duration: 36 months (update: 42 months)

Consortium: 13 partners located in Europe and Latin America

Coordinator:

Dr. V. H. Sanchez Espinoza, Karlsruhe Institute of Technology (KIT), Institute for Neutron Physics and Reactor Technology (INR)

Funding: 4.045.133,75€

McSAFER KICK-OFF MEETING

28.-30. September 2020

On September 28th-30th, the McSAFER consortium assembled for an online Kick-off Meeting. During the event, the project goals were discussed and first steps planned.